An operations manager is the person who keeps a business running smoothly every day. They make sure everything goes as planned—like a captain guiding a ship. From managing teams and solving problems to tracking performance and improving how things work, their job touches every part of a business. If you’ve ever wondered what an operations manager does, this guide will explain it in the simplest way possible.

What Does an Operations Manager Do All Day?

Operations managers wear many hats. Their job is to make sure a company works the way it should. Every day, they plan, check, guide, talk, and fix. It’s like being the “go-to” person who knows how everything fits together and makes sure it keeps moving.

In a single day, an operations manager might check production schedules, talk to team leaders, review sales numbers, fix supply chain issues, and still find time to improve a company process. They don’t just sit at a desk—they’re often in meetings, walking around the floor, or answering calls to solve small problems before they grow bigger.

They’re the bridge between the team doing the work and the top bosses making big decisions. Their job is to keep everyone on track and working toward company goals.

Main Duties of an Operations Manager

The main duties of an operations manager revolve around improving business performance. They are the ones who make sure the business has the people, tools, and systems needed to deliver good results every day. Here are just a few important duties:

- Setting clear goals for departments

- Making budgets and sticking to them

- Keeping operations on schedule

- Making sure workers have the tools and support they need

- Analyzing business performance

- Reporting results to senior management

- Creating policies and procedures

- Managing costs and resources efficiently

- Making customer service better

- Ensuring workplace safety and compliance

Whether it’s a retail store, a manufacturing plant, or a logistics center, the operations manager responsibilities remain focused on running things effectively and efficiently.

Daily Responsibilities Explained

The day-to-day tasks of an operations manager may look different depending on the industry, but most follow a pattern. The typical daily tasks of an operations manager include a mix of planning, fixing, talking, and checking.

Planning Work and Schedules

Before anything gets done, a good plan needs to be in place. Operations managers spend part of their day building and reviewing schedules for teams. They make sure there are enough workers for each shift, enough supplies for production, and that all tasks are completed on time. If something goes off track, they adjust the plan quickly to avoid delays.

Fixing Problems Fast

Problems happen every day in every business. Maybe a machine breaks down, or a supplier is late, or a worker calls out sick. Operations managers are trained to respond fast. They analyze what’s going wrong, figure out how it affects the workflow, and solve it before it becomes a bigger issue. It’s all about keeping the business moving with as little disruption as possible.

Talking to Teams and Leaders

Communication is a big part of the job. An operations manager must talk to different teams—like customer service, finance, warehouse, or sales—and also report back to higher-level managers. They share updates, explain goals, give instructions, and listen to feedback. Good communication helps everyone stay on the same page and keeps the work running smoothly.

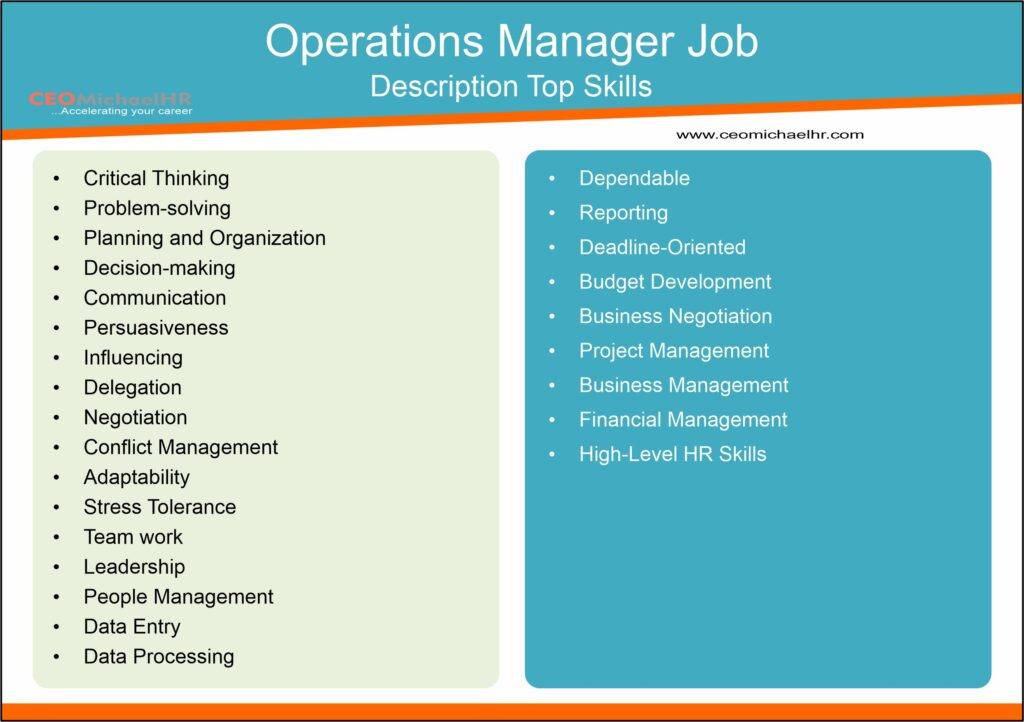

Must-Have Skills for an Operations Manager

To do their job well, operations managers need a mix of hard skills (like using software or understanding logistics) and soft skills (like communication and leadership). Some of the most important skills needed for an operations manager include:

- Leadership – They lead teams and guide people to success.

- Time management – They must keep everything on track.

- Problem-solving – When something breaks, they fix it fast.

- Communication – They explain things clearly and listen well.

- Analytical thinking – They look at data and make smart decisions.

- Organization – They juggle many tasks at once.

- Technical knowledge – They understand the systems, software, and tools used in their business.

- Budgeting – They manage money wisely and prevent waste.

- Customer focus – They help deliver great service and products.

A great operations manager doesn’t just keep things running—they make things better over time.

Who Do They Work With?

Operations managers work with a wide range of people every day. They’re the link between workers and upper management. They may report directly to a general manager, plant manager, or even a company director depending on the business size.

They also work with:

- Team leaders

- Department heads

- HR managers

- Sales and marketing teams

- Supply chain and logistics coordinators

- Frontline employees

- Customers or clients (especially in service industries)

They must understand everyone’s role and help them work together. The better an operations manager is at teamwork and communication, the better the company runs.

Where Do Operations Managers Work?

Operations manager jobs exist in almost every industry. If a business has daily processes, it needs someone to manage them. You’ll find operations managers in:

- Retail chains – managing multiple stores and sales operations

- Warehouses and logistics centers – making sure goods move on time

- Manufacturing plants – keeping machines running and quality high

- Restaurants and hospitality – ensuring customers have great experiences

- Healthcare facilities – organizing care and support services

- Construction companies – scheduling teams and materials

- Tech companies – improving internal processes and workflows

Job Titles That Are Similar

Not every company uses the same title. Some job titles that are very similar to “operations manager” include:

- Operations Supervisor

- Operations Lead

- Team Leader – Operations

- Area Manager

- Logistics Manager

- Production Supervisor

- Business Operations Manager

Business Operations Manager

A business operations manager focuses more on internal business processes than physical production. They may work in a corporate office, managing data, strategy, budgeting, and performance. They are like the “brains behind the scenes” making sure systems and goals line up.

Plant Manager

A plant manager works mostly in manufacturing or industrial settings. They manage the workers, machinery, materials, and production lines. While an operations manager might work in various industries, a plant manager is very specific to physical production. Both roles focus on efficiency and output, but plant managers usually deal with more technical systems.

General Manager

A general manager (GM) is typically a step above the operations manager. While the operations manager handles the day-to-day tasks, the general manager focuses on bigger-picture goals like growth, profit, and strategy. However, in smaller companies, the GM might also take on the responsibilities of an operations manager. The difference between general manager vs operations manager often comes down to scope: GMs lead the whole business unit, while operations managers focus on how work gets done.

The Bottom Line

The job of an operations manager is all about keeping everything running smoothly. From people and processes to budgets and business performance, they are the glue that holds a company together. Their role changes from day to day, but their goal is always the same: make things better, faster, and more efficient.

Whether you’re thinking of applying for this role or just trying to understand it, remember this: operations managers are problem-solvers, leaders, planners, and team players—all rolled into one. If you enjoy organizing, leading, and improving things, this could be the perfect job for you.