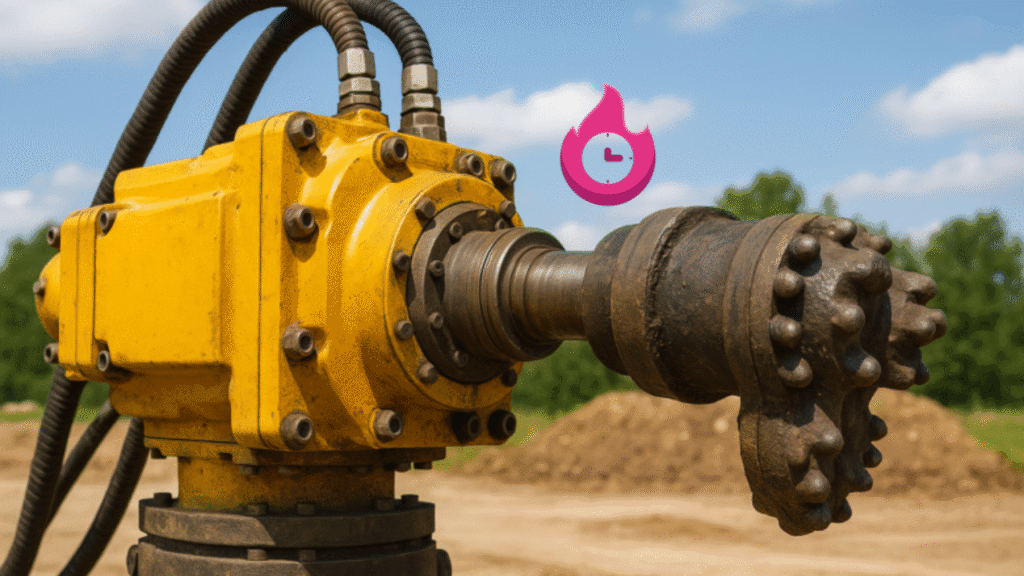

If you have ever wondered how giant machines can drill through rock, dig deep tunnels, or move tons of soil without stopping, the answer often lies inside a very special gearbox. This gearbox is called a Spezialbohrgetriebe, and it may sound complicated, but it is actually a simple idea that powers some of the toughest machines in the world. Today, we will explain what it is, why it is so important, where it is used, and why engineers trust it for big jobs.

What Is a Spezialbohrgetriebe?

A Spezialbohrgetriebe is a type of gearbox that is specially built for drilling and boring machines. The word may look German, but in English, it simply means “special drilling gearbox.” While normal gearboxes are used in cars, bikes, or machines to transfer power from the engine to the wheels, a Spezialbohrgetriebe is designed to handle much heavier loads, stronger pressure, and nonstop work in harsh conditions. It takes the power from a motor and turns it into the perfect speed and torque that drilling equipment needs. Torque is just a technical word for force, and speed is how fast the machine spins. Together, these two things decide how well a machine can drill.

Why Do We Need Spezialbohrgetriebe?

The main reason we need Spezialbohrgetriebe is that normal gearboxes cannot handle the extreme jobs that come with drilling, mining, or tunnel construction. Imagine trying to dig through rock with a normal power tool—it would break within minutes. But when machines are fitted with a Spezialbohrgetriebe, they can keep working day and night without failure. These gear systems are built to deliver controlled power, meaning they can slow down the spinning while increasing the pushing force. This balance makes it possible to cut through hard rock, soil, or even underwater ground safely and efficiently. Without such gearboxes, modern cities would not have underground railways, big water pipelines, or tall skyscrapers because drilling is the first step in making them possible.

Where Are These Gearboxes Used?

Spezialbohrgetriebe are not found everywhere, but when you look at huge construction projects, mining sites, or tunnel projects, you will surely find them. They are part of drilling rigs, boring machines, and other heavy-duty systems that need reliable and powerful gear control.

Big Building Projects

In large construction projects like building bridges, airports, dams, and skyscrapers, Spezialbohrgetriebe are used in drilling rigs that prepare the foundation. The foundation is the most important part of any building because it holds the weight of everything above it. By using a Spezialbohrgetriebe, workers can drill deep holes into the ground, insert strong pillars, and make sure the building will not shake or collapse. In the United States, where cities are expanding with tall structures, these gearboxes are part of almost every major building project.

Mining Work

Mining is one of the toughest industries on earth. Workers need to dig deep to reach coal, gold, copper, or other valuable minerals. The machines used in mining cannot survive without heavy-duty gearboxes like Spezialbohrgetriebe. These gear units allow machines to cut through solid rock and move materials quickly. In underground mines, where safety is critical, the gearboxes must not only be strong but also reliable so that workers are protected from accidents. That is why mining companies prefer Spezialbohrgetriebe because they are trusted for their durability, power, and efficiency.

Tunnel Construction

Have you ever traveled through a long tunnel by car or train? Those tunnels were made possible by huge tunnel boring machines (TBMs), and inside every TBM, there is a Spezialbohrgetriebe working hard. Tunnel construction is one of the most complex jobs in engineering because machines must dig underground while keeping everything safe above ground. The gearbox helps control the massive cutting wheel of the TBM, making sure it turns at the right speed and with enough force to cut through soil, sand, and stone. Without such gear systems, modern transportation tunnels and metro lines would not exist.

How Does a Spezialbohrgetriebe Work?

The working principle of a Spezialbohrgetriebe is simple but powerful. It connects the motor to the drilling tool and changes the energy into the right mix of torque and speed. If you think of a bicycle, when you go uphill, you shift gears to make pedaling easier but slower. That is exactly what the Spezialbohrgetriebe does, but on a much larger scale. It uses specially designed gears that are made of hardened steel to handle extreme pressure. These gears transfer the motor’s energy smoothly and allow the drilling head to push through any material. Inside the gearbox, there are lubricants to reduce heat and friction, and seals to prevent dust, water, and dirt from entering. The result is a smooth, reliable operation even in the harshest environments.

Types of Spezialbohrgetriebe

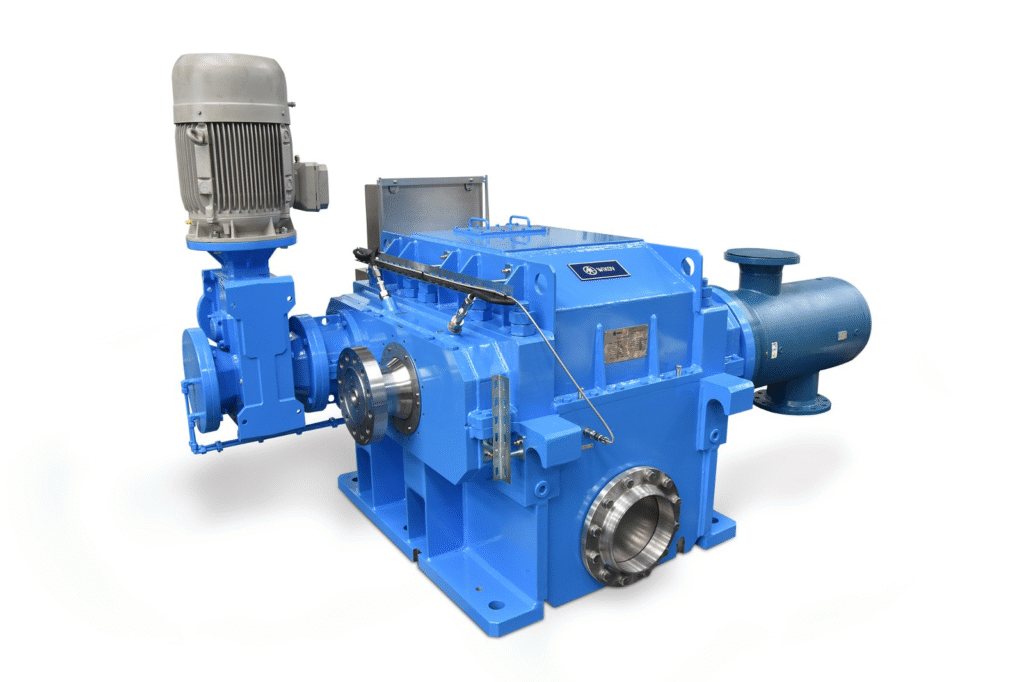

Not all Spezialbohrgetriebe are the same. Depending on the project, engineers choose from different types. Some are designed for vertical drilling in foundation work, while others are made for horizontal boring in tunnels. There are compact models for smaller rigs and giant models for tunnel boring machines. Some gearboxes use planetary gear systems, which are very efficient and compact, while others use helical gear systems for smoother operation. The type depends on the machine, the soil or rock condition, and the amount of torque needed.

What Makes It “Special”?

So what makes the Spezialbohrgetriebe special compared to normal gearboxes?

Built for Hard Jobs

These gearboxes are built to handle extreme force, high pressure, and nonstop working conditions. They are made from strong steel alloys, precision-engineered parts, and tested under heavy loads. While a car gearbox may last 10 years, a Spezialbohrgetriebe can last decades if maintained properly.

Designed for Safety

Safety is a top priority in construction, mining, and tunneling. A faulty gearbox can cause accidents, machine breakdowns, or even dangerous collapses. Spezialbohrgetriebe are designed with extra safety features such as overload protection, fail-safe systems, and high-strength casings. These features make sure that even under extreme stress, the gearbox will keep workers safe.

Easy Maintenance Tips

Another special quality is that they are designed for easy maintenance. Engineers can quickly check oil levels, replace seals, or inspect gear teeth without dismantling the entire machine. Regular maintenance like lubrication, cleaning, and inspection helps the gearbox work longer and prevents expensive repairs. Simple tips like using the right lubricant, avoiding overloading, and scheduling regular service keep the gearbox in top shape.

What to Look for Before Buying One

If a company wants to buy a Spezialbohrgetriebe, there are some important things to check. First is the torque capacity, because the gearbox must handle the load of the project. Second is the durability, which depends on the material and design. Third is compatibility with the drilling machine. Buyers should also look at after-sales service, spare parts availability, and energy efficiency. Choosing the right Spezialbohrgetriebe can save time, reduce costs, and improve safety in any project.

The Bottom Line

The Spezialbohrgetriebe may sound like a complex piece of machinery, but at its heart, it is simply a strong and smart gearbox that makes the toughest jobs possible. From tall skyscrapers to deep mines and long tunnels, this gearbox is the hidden hero that powers the machines shaping our modern world. Built for strength, designed for safety, and made for reliability, it shows how engineering can turn difficult challenges into successful projects. Whether you are an engineer, a student, or just curious, now you know why the Spezialbohrgetriebe is so important and why it will continue to play a big role in building the future.